System Introduction & Technical Parameters

System Introduction

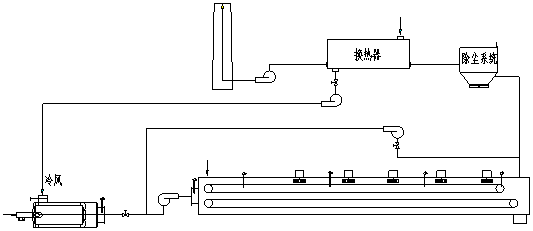

1. Common System Configuration (for Flap Dryer, Single-board Dryer, Slime Dryer)

1.1 Combustion Section

●Gas and combustion-supporting air achieve automatic combustion under PLC control.

●Part of the cold air is mixed with the hot gas after combustion after heat exchange, to fully utilize thermal energy.

1.2 Drying Section

●The main body of the drying section is a heavy-duty chain plate dryer. Its basic mechanical movement principle is similar to that of a chain grate,

and it can be regarded as a low-temperature chain grate.

●Material Flow: After passing through the distributor, materials fall into the tail of the upper layer of the dryer, and are discharged from the head of the lower layer in sequence.

●Crushed Materials: During drying and transportation, some crushed materials fall into the bottom.

They are transported to the tail of the lower layer by the chain plate conveyor in the lower layer, and then sent out by the scraper conveyor.

This system is a fully enclosed system.

●Hot Air Flow: Hot air enters the drying chamber through the distribution box.

There is a turbulence system inside the drying chamber to realize strong convection of hot air to materials and improve drying efficiency.

●Materials and hot air are dried through full strong convection exchange.

At the same time, the hot air turns into dusty wet air and is discharged.

Part of the exhaust gas is returned to the air distribution system of the dryer to fully utilize thermal energy,

and the other part is discharged into the atmosphere after passing through the heat exchanger and dust collector.

1.3 Dust Removal Section

It is mainly used to treat the dusty wet air discharged from the dryer.

●Dry dust removal is adopted when the gas temperature is much higher than the dew point temperature.

●Dynamic wave wet dust removal is adopted when the gas temperature is lower than or close to the dew point temperature.

1.4 Heat Exchange Section

●Generally, no heat exchanger is needed when wet dust removal is adopted.

●The heat exchanger is also not required when dry dust removal is adopted but the exhaust gas temperature is low.

2. Technical Features

●The hot blast stove can realize fully automatic air distribution and automatically control the hot air temperature as needed.

●Maximize the use of thermal energy, thereby reducing fuel consumption and achieving the goal of energy conservation.

●Some links of the drying system can be omitted according to specific conditions, such as the heat exchanger.

HGW Horizontal Dryer

Application Scope

It is mainly used for drying shaped balls, and can also be used for drying fragile block materials, such as cold-bonded pellets, briquette coal, briquette coke, etc.

It is mainly used for drying shaped balls, and can also be used for drying fragile block materials, such as cold-bonded pellets, briquette coal, briquette coke, etc.

Principle & Structure

It is a drying equipment based on the one-way conveying principle.

●Shaped balls with a certain moisture content flow into the upper chain plate of the dryer from the tail of the dryer through the feed hopper.

●The materials run stably to the head of the dryer through the chain plate, and the shaped balls are gradually dried under the baking of hot air.

It is a drying equipment based on the one-way conveying principle.

●Shaped balls with a certain moisture content flow into the upper chain plate of the dryer from the tail of the dryer through the feed hopper.

●The materials run stably to the head of the dryer through the chain plate, and the shaped balls are gradually dried under the baking of hot air.

3. Outstanding Features

1. The heat source can be electric heating, or hot air heating (hot air after heat exchange with fuel oil, coal, gas or superheated steam).

2. It can significantly reduce the breakage rate of shaped balls.

3. It is equipped with an automatic tensioning device.

Springs (for dryers with short length) or hydraulic systems (for dryers with long length) are used to ensure stable operation of the chain

plate (mesh belt) without chain dropping, jamming or deviation.

4. The sieve plate is made of heat-resistant steel punched into a mesh shape, with high strength, no easy deformation and good air permeability.

5. The chain plate is driven by a speed-regulating motor. The running speed can be adjusted as needed to control the drying time.

6. The temperature of each section in the kiln body is displayed digitally, which is convenient for mastering and controlling the temperature in the kiln.

7. A turbulence system is designed to enable strong convective heat exchange between hot air and materials.

Safety Measures

Mechanical Protection

Once a mechanical failure occurs and the temperature is too high, the system will immediately cut off the heat source and prevent fire through the safety protection device.

Once a mechanical failure occurs and the temperature is too high, the system will immediately cut off the heat source and prevent fire through the safety protection device.

Equipment Specifications

The equipment is designed and manufactured in accordance with the specific working conditions. The maximum single machine processing capacity can reach 200t/h, and the maximum chain plate width can reach 4m.

The equipment is designed and manufactured in accordance with the specific working conditions. The maximum single machine processing capacity can reach 200t/h, and the maximum chain plate width can reach 4m.

Contact us

Fixed line: +86-379-65195189

Mobile/Wechat/Whatsapp: 13838843223

Email: info@lykzhb.cn/ sales@lykzhb.cn

Company address:501/502,Building No. 1, Zone B,Luoyang University Science and Technology Park, Luoyang City, Henan Province, China.

Factory address: No. 18, Fuxin Rd, Luoxin Industry Park, Luoyang City, Henan Province, China

Fixed line: +86-379-65195189

Mobile/Wechat/Whatsapp: 13838843223

Email: info@lykzhb.cn/ sales@lykzhb.cn

Company address:501/502,Building No. 1, Zone B,Luoyang University Science and Technology Park, Luoyang City, Henan Province, China.

Factory address: No. 18, Fuxin Rd, Luoxin Industry Park, Luoyang City, Henan Province, China

Copyright © 2024 Luoyang Kaizheng environmental protection processing equipment Co., LTD